Discharge Control

for oil injected screw compressors

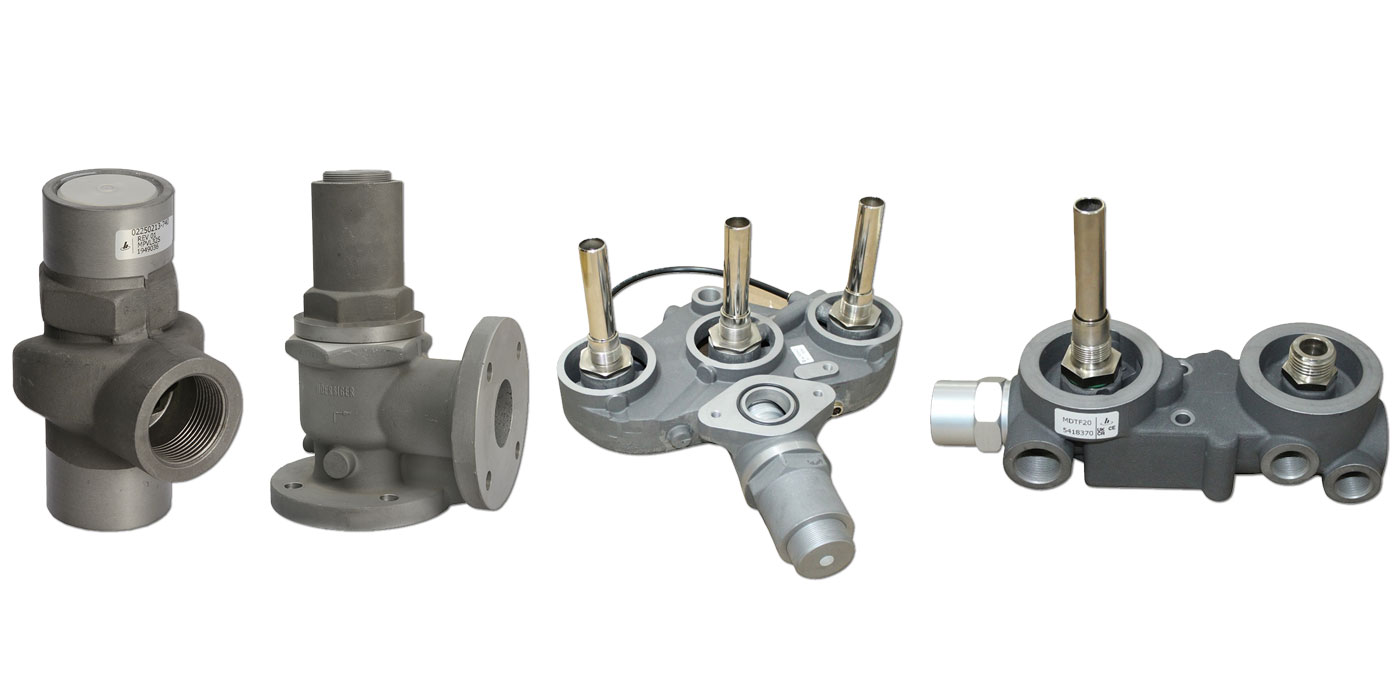

Discharge control components ensure that the minimum oil flow required for cooling and lubricating the compressor is maintained during start-up and off-load and when the user lines are fully open. Optional combinations with filtrations and oil temperature regulation possible.

Ensure the oil flow by keeping a minimum pressure level in the compressor. The integrated check valve prevents back flow from air-net during stop and idling.

MPVL:

Functional tube connector/ Component of the pressure line after oil separation

MPVL ETS:

Allows integration into customer components (e.g. separator tank, air cooler)

- Volume air flow:

- MPVL: 0.6 to 200 Nm3/min I 22 to 7100 scfm

MPVL ETS: Depends on customer Housing - Maximum working pressure:

- Standard 16 barg I 232 psig

High pressure 40 barg I 580 psig on demand - Ambient temperature:

- -20 to + 120 °C I -4 to +248 °F

- Inlet/outlet connections:

- Threaded or flanged

Type: MPVL15-80, MPVL3" and MPVL4"

Combination of minimum pressure valve and oil thermostatic valve with housing for spin-on filters.

MD:

Combination of minimum pressure valve and air/oil separator

MDTF:

Combination of minimum pressure valve, oil thermostatic valve with air/oil separator and oil filter

- Volume air flow:

- MD: 5 to 26 Nm3/min I 205 to 920 scfm

MDTF: 2 to 6 Nm3/min I 70 to 200 scfm - Maximum working pressure:

- 16 barg I 232 psig

- Ambient temperature:

- -20 to +120 °C I -4 to +248 °F

- Thermostat setting (for MDTF only):

- 55 to 70 °C I 131 to 158 °F

70 to 85 °C I 158 to 185 °F

71 to 80 °C I 160 to 176 °F

73 to 88 °C I 163 to 190 °F - Oil flow (for MDTF only):

- 45 to 80 l/min I 11 to 22 gal/min

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.