HydroCOM – Stepless Capacity Control System

HydroCOM is a stepless and fully automated capacity control system for reciprocating compressors. Often a reciprocating compressor delivers more gas than required by the process. This is due to the physics and design of the compressor as well as the fluctuations in the process. The operating principle of the HydroCOM is based on the reverse flow principle. This means that only the gas flow that is needed for the process is compressed. This avoids the reuse of process gas and the cost of electrical energy for the driver can be significantly reduced, thus increasing the profitability of your plant.

When efficient part load is required, the HydroCOM system allows a simpler compressor design, with significantly fewer cylinders, compared to on/off control. In addition, individual adaptation, to your needs, of the hydraulic unit is possible.

How does the HydroCOM system work?

Around 1,600 systems are currently in reliable operation. The hydraulic HydroCOM actuators enable fast and precise control without any loss of performance, if required even from 10* to 100 percent within three revs. The wide, stepless volume control range thus ensures optimum process control. Thanks to the interface to PLC or process controller, the HydroCOM allows fully automated control. Reliable and standardized components drastically minimize the risk of unplanned downtime.

* depends on application

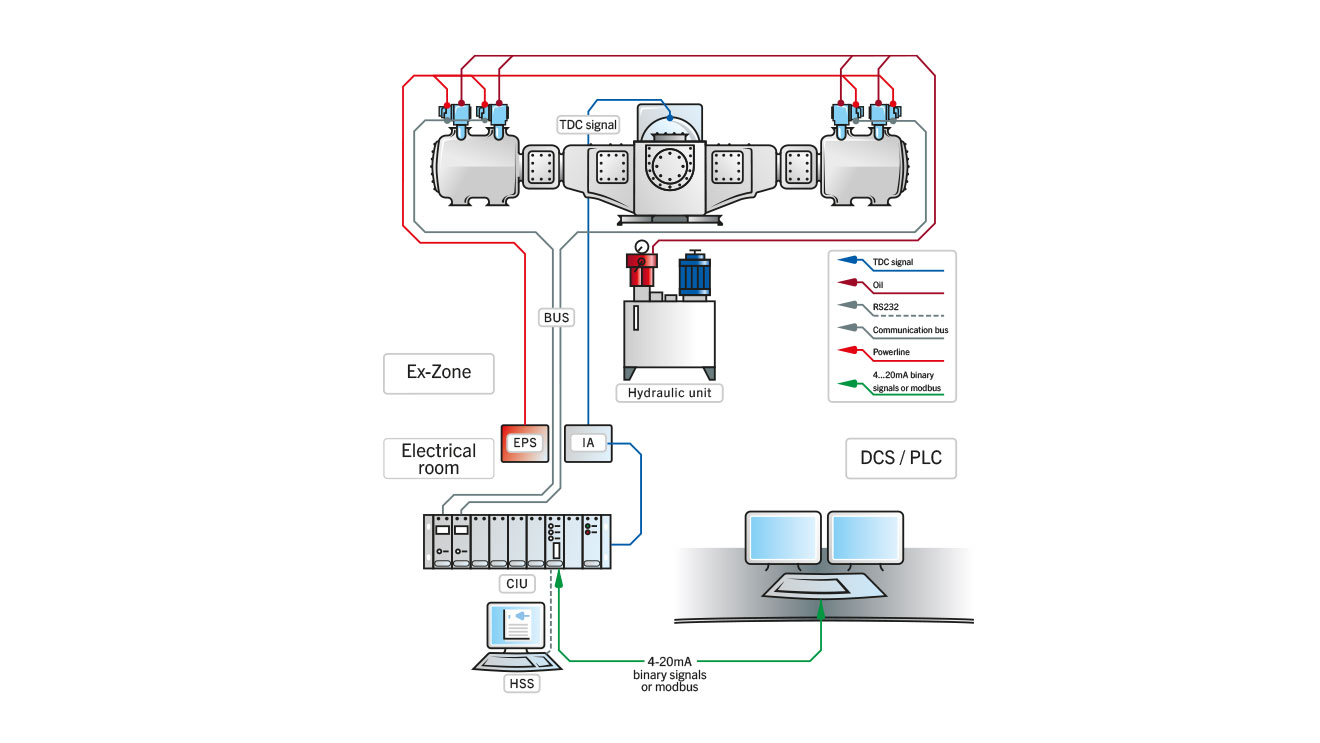

Due to its modular design HydroCOM is easy to integrate into both existing and new compressor installations. Process control tasks are implemented ideally in a PLC or a loop controller. In a control cabinet the HydroCOM “Compressor Interface Unit” (CIU) carries out data exchange between PLC and HydroCOM actuators. Embedded temperature monitoring of suction valve covers allows insight into compressor conditions such as leaking valves.

- Up to 6,800 N unloading force

- Control range: 10*…100% (*depending on application)

- Max. suction pressure: 160 bar / 2,320 psi

- Max. compressor speed: 1,200 rpm

- Maintenance reminder signal and serial interface

- Stainless steel hydraulic unit version available

- Suited for corrosive environment: yes

- Suited for non-lube applications: yes

- Ex certification: EU (ATEX, IECEx), US (FM), Canada (CSA), Japan (TIIS), Russia (EAC), Korea (KCs), Taiwan (Safety level), Brazil (INMETRO), China (Nepsi Ex), India (CCOE)

Your benefits at a glance

- Lower investment and maintenance costs for multistage, efficient compressors as well as emissions reduction (“carbon footprint”)

- Reduced energy and emissions costs

- Increased reliability, efficiency and minimized risk of unplanned downtimes

- Complete and easy integration into the control system as well as easy upgrade and integration for existing compressors

Downloads

Brochure A4 Format

Brochure Letter Format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.