REE – Reliable, Efficient, Environmentally sound

Maximize your entire fleet’s performance

REE is an integrated consulting approach that is unparalleled in the oil and gas industry. We focus not only on the performance and emissions levels of individual components or compressors, but on their interaction in the plant processes. This will help your business perform better and grow sustainably.

Want more insights on your compressor fleet performance? With REE you’ll get the answers you’re looking for to reach your goals.

Recips are critical to many processes in the plant. We map your recips and rank the performance of each with regard to its current purpose within your fleet – starting from one compressor; single-site or multi-site wide. Our REE Index benchmarks your machines against the industry standard.

Together with you, we create a fleet development plan. We align priorities to improve your fleet in terms of reliability, efficiency and environmental soundness defined by areas with the largest savings potential, and provide you with the best business case.

Our recip performance experts develop concrete solutions for the compressors that have been prioritised for improvement, following an on- or off-site audit. We plan and implement solutions over a defined period, all in line with your maintenance schedule.

- OPEX

- Savings Potential

We thought we knew everything about our compressors and how to employ them optimally. HOERBIGER’s REE team impressively demonstrated how much more knowledge could be extracted from the operating data and inspection of every single machine. There was a lot to be gained by including the requirements of process management in the audit. Now we have 40 detailed analyses indicating numerous ideas for sustainable improvements.

„

Considering reliability, efficiency and environmental aspects

We understand that an individual component or its performance is not your biggest problem. That is why we look at the entire compressor and the interaction in the process and with other equipment. That's how we can describe how you can improve performance beyond the status quo.

Based on facts – previous and present performance of your machines – we can describe and document the necessary improvements to further increase the reliability of your reciprocating compressors and the fleet. Data drives the analysis and helps identify where to improve to eliminate bad actors.

Are you managing conflicting goals in the team? Driving sustainability can be a challenge, when different actors have different priorities. We help you understand the status quo and identify the blind spots. Our analysis, prioritizations and business cases help you convince your peers of necessary improvements. For a better tomorrow!

It’s important to understand that there is no one magic solution that will fix all maintenance-related problems. Maintenance is crucial to the performance of each compressor. Unexpected downtime is reduced by optimizing your maintenance strategy and standardizing components. This makes it easier to plan maintenance, stock parts and increase the reliability of the machines.

Constant improvements are crucial to stay in business in the long run. At the same time, sustainability goals and emission standards are tightening. REE is your tool to balance the different needs and prioritize between necessary investments. Stay online, increase performance and reach your goals with your existing fleet.

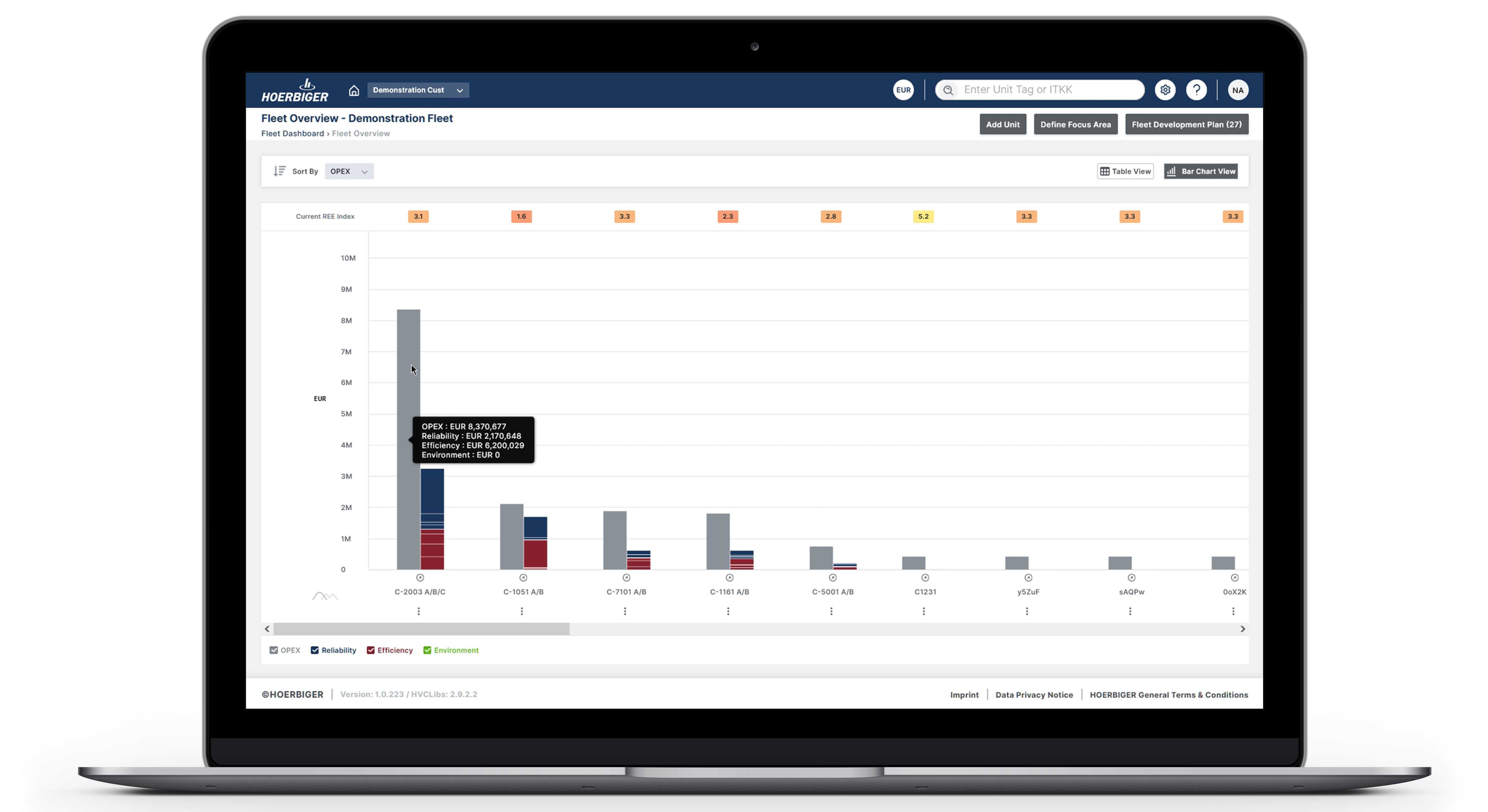

One interface to view your fleet’s performance and improvement potential

Our proprietary Fleet Performance Platform determines key performance parameters and benchmarks these against the industry’s best performer. The analysis examines each compressor of a single- or multi-compressor unit individually and ranks the reciprocating compressor fleet as a whole. This way we can provide you with a bird’s eye view and uncover hidden potential.

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.