HCP 500 – Hydrogen Compressor Package

Achieve high mass flow hydrogen compression

Contact

If you have any questions about the HCP 500, please contact us here.

HCP 500: Over a century of expertise in compression technology

Hydrogen is a key element of the green energy transition and will play a significant role in the decarbonization of industry and transportation. However, on this path, the necessary facilities must be scaled, industrialized, and optimized in terms of their total cost of ownership (TCO). Our technology already offers all of this today – safe, reliable, and cost-effective hydrogen compression for large-scale hydrogen applications, focusing on trailer filling and heavy-duty hydrogen refueling.

Regardless of the production method, the transport and storage of the molecule is a central issue for the future hydrogen economy. Our HCP 500 is designed to process hydrogen from various sources and allows for the filling of different storage media at varying pressure levels. The advantage is that the control system eHydroCOM precisely adjusts the compressor load to the changing operating conditions of the electrolyzer. Typical sources / targets for the HCP 500:

- Electrolyzers

- Trailers

- Cascade storage tanks

important role in the transition to emission-free commercial vehicles in the transportation sector. The HCP 500 addresses key points for future operators of refueling stations, such as short refueling times for large fleets and the possibilities of "direct filling". Refueling of:

- Trucks

- Buses

- Trains

- Ferries

FAQ

Is the compressor oil-free (i.e., non-lube)?

Yes, the compressor is oil-free. We guarantee that the wear of our sealing elements doesn’t degrade the quality of H2.

What is the footprint of the Hydrogen Compressor Package?

~72 m2 incl. maintenance and service area.

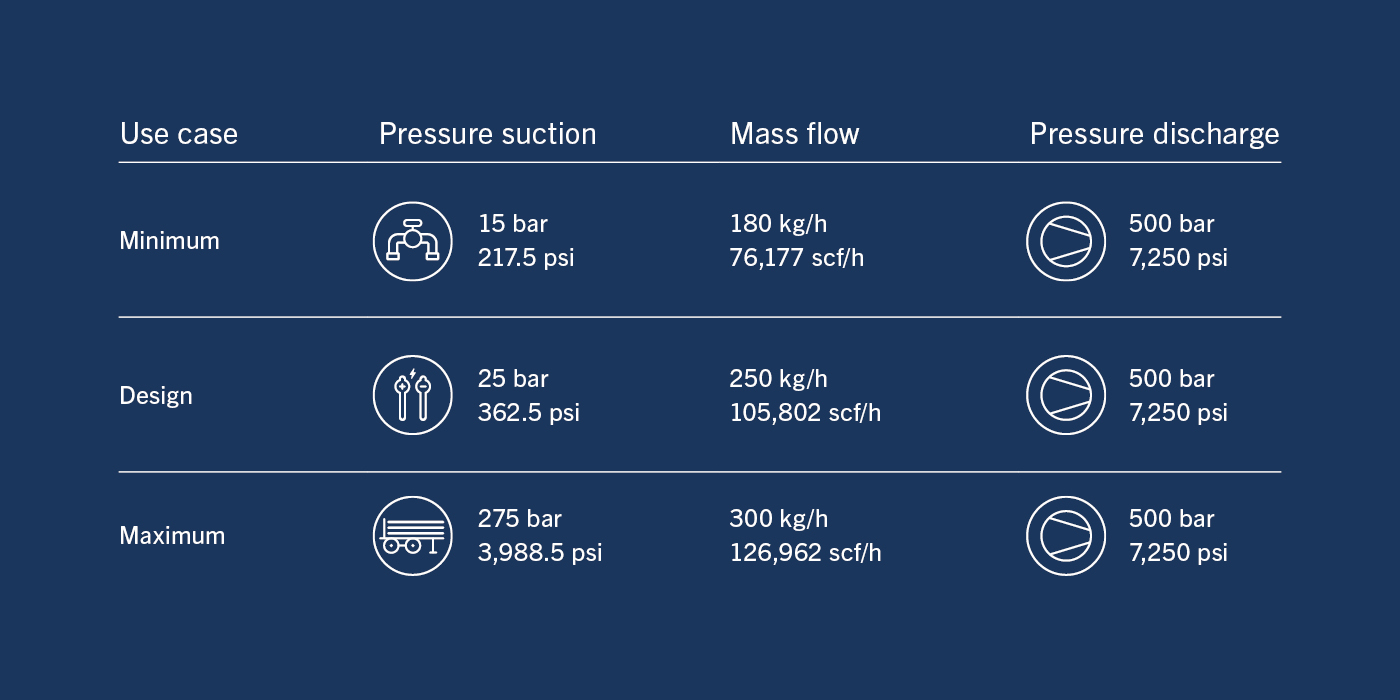

What is the suction pressure and discharge pressure for the Hydrogen Compressor Package?

The design suction pressure is 25 bar. A suction pressure range from 15 – 275 bar is possible. The discharge pressure is maximum 500 bar, but flexible in a range from 50 to 500 bar.

What is the mass flow of the Hydrogen Compressor Package?

At design conditions the mass flow is 250 kg/h. Based on the supply and discharge condition the mass flow can be in a range of 180 kg/h to 300 kg/h.

How quickly does the compressor respond to load changes?

The compressor responds almost instantly to load changes with our eHydroCOM HD stepless control system. That’s particularly useful to stabilize the backpressure in mbar range for electrolysis.

What design guidelines and engineering standards have been followed?

CE (EU Declaration of Conformity), ATEX (2014/34/EU), Pressure Equipment Directive (2014/68/EU), Machinery Directive (2006/42/EG), Low Voltage Directive (2014/35/EU), Hydrogen Quality (SAE J2719), Hydrogen Piping (EN 13480, EN 10204), and many others.

What safety and reliability standards have been followed?

HAZOP / HAZID study according to EN 61511, SIL Verification according to ISO 13849-2 and IEC 62061, Hazardous area classification / drawing, Explosion protection documentation / design, H2 Piping – stress analysis, TVA (Tortional Vibration Analysis), Skid and foundation engineering according to but not only API 684-2 and DIN ISO 20816, Heat exchanger engineering concerning a fail-safe design according to API 250 and API 521, and many others.

Do you provide maintenance service of the Hydrogen Compressor Package?

Yes, we offer complete maintenance of the Hydrogen Compressor Package that is supported by our global service organization: 1000+ employees in 44 countries and 71 locations.

Components used for the Hydrogen Compressor Package

- Profiled plate valves (XP/CP/CPs Valve)

- Sealing solutions (rings-and-packings.hoerbiger.com)

- Flow control (eHydroCOM)

Your benefits at a glance

| Features | Advantages | Benefits |

|---|---|---|

| High mass flows even at low suction pressure, starting from 15 bar / 217.5 psi | Continuously high mass flow | Less compressors |

| Fast fill / short refill time | ||

| Less buffer storage / high pressure | ||

Utilization of the eHydroCOM, an Electric Stepless Capacity Control System | Stepless compressor capacity control (0 – 100%) | Process control and thus perfect adaptation to the fluctuating operating conditions of electrolyzers |

| Favorable acquisition and operating costs compared to frequency converters or bypass controls | Energy-efficient compressor operation, resulting in cost savings, especially in partial load operation | |

| Packaged turnkey solution with a high degree of standardization, professionally supported by a global service organization | “One stop shop” that covers installation to spare parts to maintenance – whole “scope” is covered | Increased compressor availability and efficiency |

| Compact design through upright recip compressor construction | Small Footprint | Good ratio of space requirements to delivery volume, leading to reduced costs and good integrability |

| Operational monitoring based on a digital twin with a high security standard | Maximize compressor operating window with real time limit adjustment, based on current operating conditions | Safe operation and increased uptime at low operating costs |

| Compressor components such as valves and sealing elements from the industry leader HOERBIGER | Development, industrialization, and product standards based on 100+ years of experience | High durability and availability |

What's new?

A4 Format

Letter Format

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.