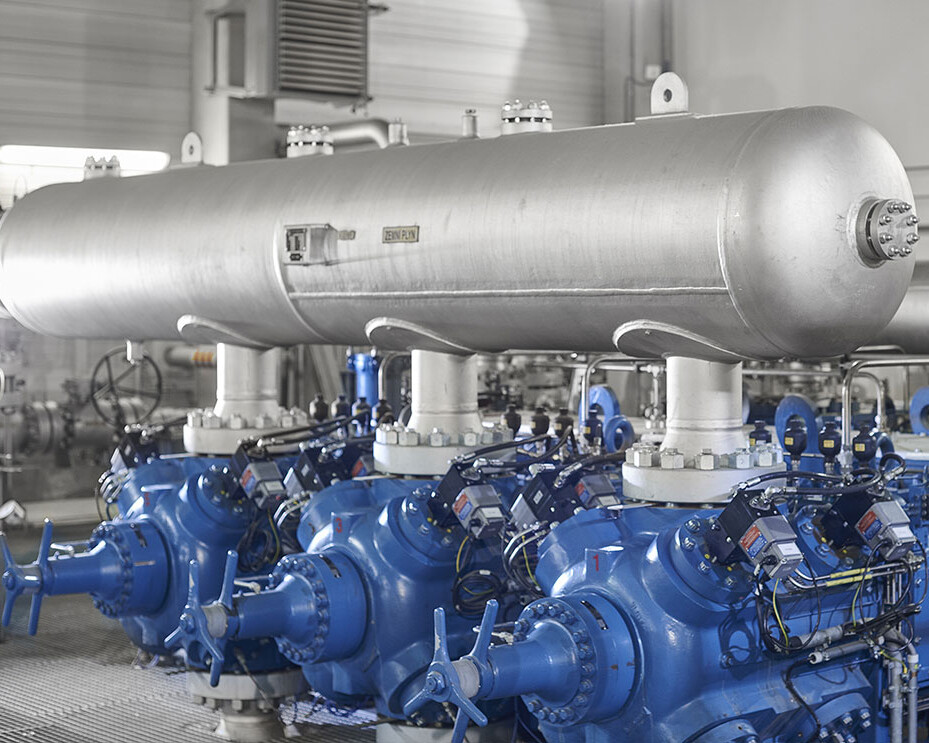

Comprehensive Compressor Service for North America

Your partner for complete recip repairs in the U.S. and Canada

Focused on your needs

At HOERBIGER, service is not just about repairing our customers’ components. It’s about meeting all of your short and longer-term service needs – by assessing components wear patterns and service histories, and identifying ways to increase reliability. With our comprehensive expertise, we can help improve the reliability, efficiency, and environmental soundness of your compressors. Our highly skilled technicians and best-in-class engineering experts deliver the timely service and upgrades you need to reach the next level of compressor operations, while also helping you meet your emissions goals.

We can help you lower your emissions and meet stricter environmental standards, while also lowering costs and maximizing your compressor and fleet efficiency. Our cutting-edge emissions products and services are proven, and specifically designed to help you reduce energy-related emissions and save money. For a better tomorrow.

Want to learn more? Visit our emissions offerings page here.

REE is a unique and integrated engineering approach that is unparalleled in the oil and gas industry. We focus not only on individual components or compressors, but also on their interaction in plant processes.

REE stands for Reliability, Efficiency and Environmental soundness. In an REE audit, HOERBIGER experts analyze and benchmark existing machines. Then they determine opportunities for optimization in terms of reliability, efficiency and environmental soundness. Thanks to REE, HOERBIGER maximizes your machines’ performance.

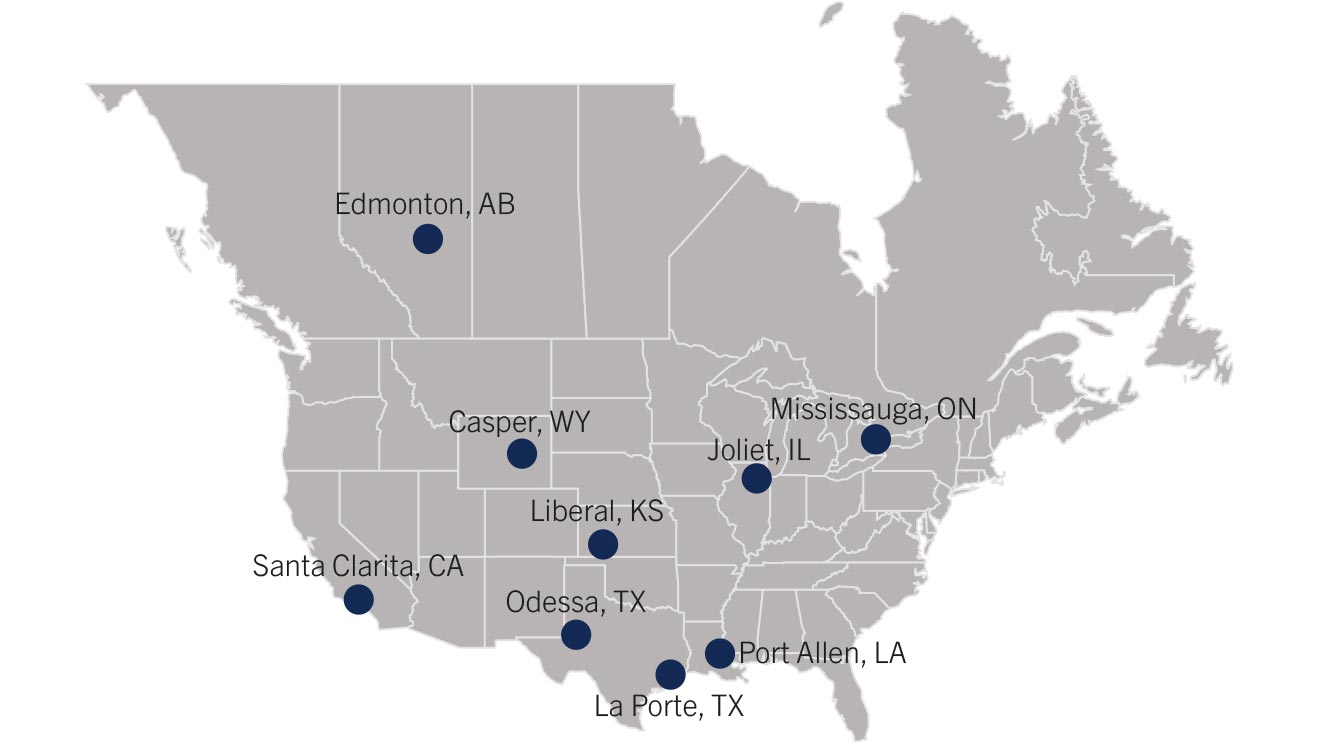

High quality services when and where you need us

HOERBIGER has been a trusted name for quality, service, and reliability for more than 125 years. Our service facilities in the U.S. and Canada are fully equipped and employ some of the most highly trained and experienced people in the business. We are committed to providing only the best customer service to help get your recip compressors back up and running quickly and at optimal levels.

Casper, Wyoming

La Porte, Texas

moved to Houston, offering same services shown in the video

Liberal, Kansas

Port Allen, Louisiana

Santa Clarita, California

- Ariel distributor

- Valve repair (CNC, HOERBIGER and all other OEMs)

- Packing case repair

- Air testing and serialization for all valves and cases

- Wiper case repair/upgrade

- Piston rod inspection/repair/upgrade

- Piston inspection/conversions

- Single and multi-piece pistons

- Piston nut torquing

- MAG particle testing

- Crossheads and pins

- Crankshafts and bearings

- Connecting rods and bushings

- Cylinder reboring/relining

- Cooler retubing

- Piston rings, rider bands and packing upgrades

- Air-to-load (ATL) & Air-to-unload (ATU) actuator designs

- Services for all reciprocating compressor makes and models

- Welding

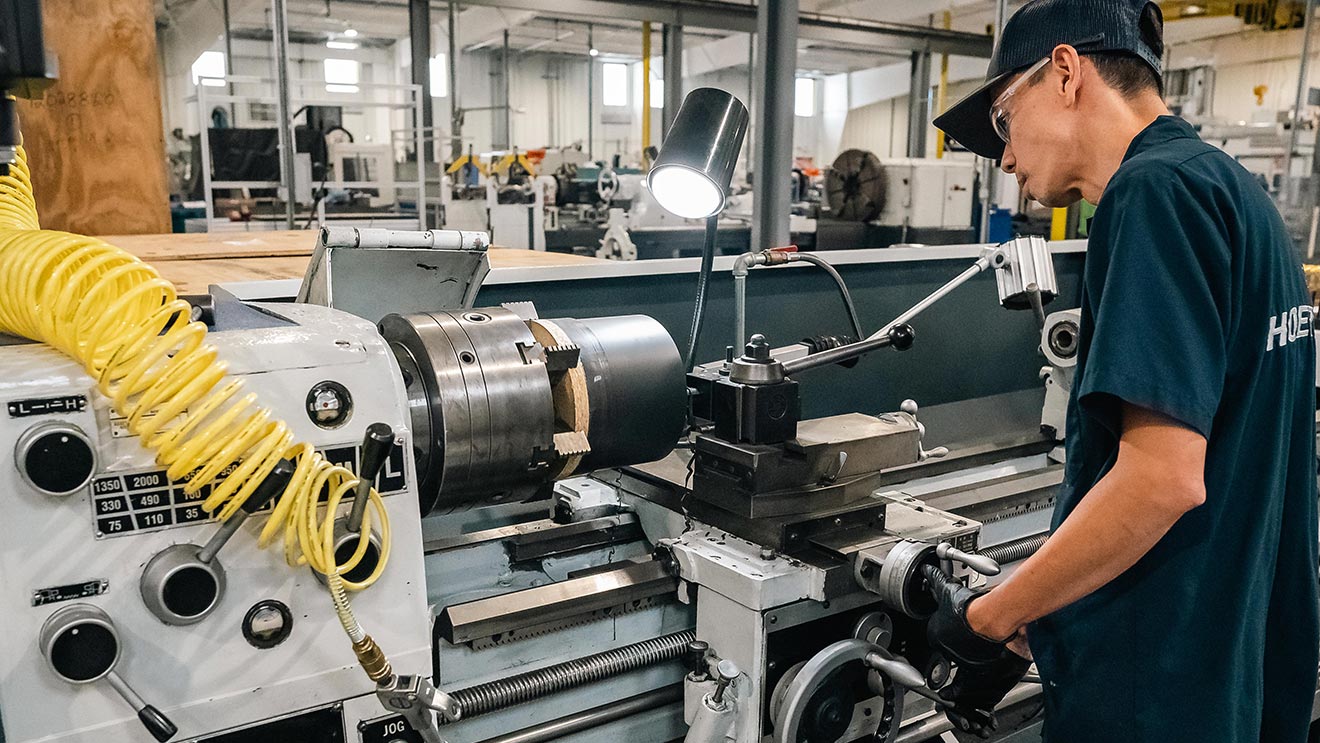

- Machining

- Rebabbitting

- Metal spraying

- Metal stitching

- Induction hardening

- Tungsten carbide coating

- Praxair CoArc™ metal spraying

- Valve upgrades (CNC, HOERBIGER and all other OEMs)

- Emissions reductions

- Rings & Packing

- Capacity control systems

- HydroCOM repair and testing

- Pistons & piston rods (including manufacturing and thread rolling)

- Cylinders

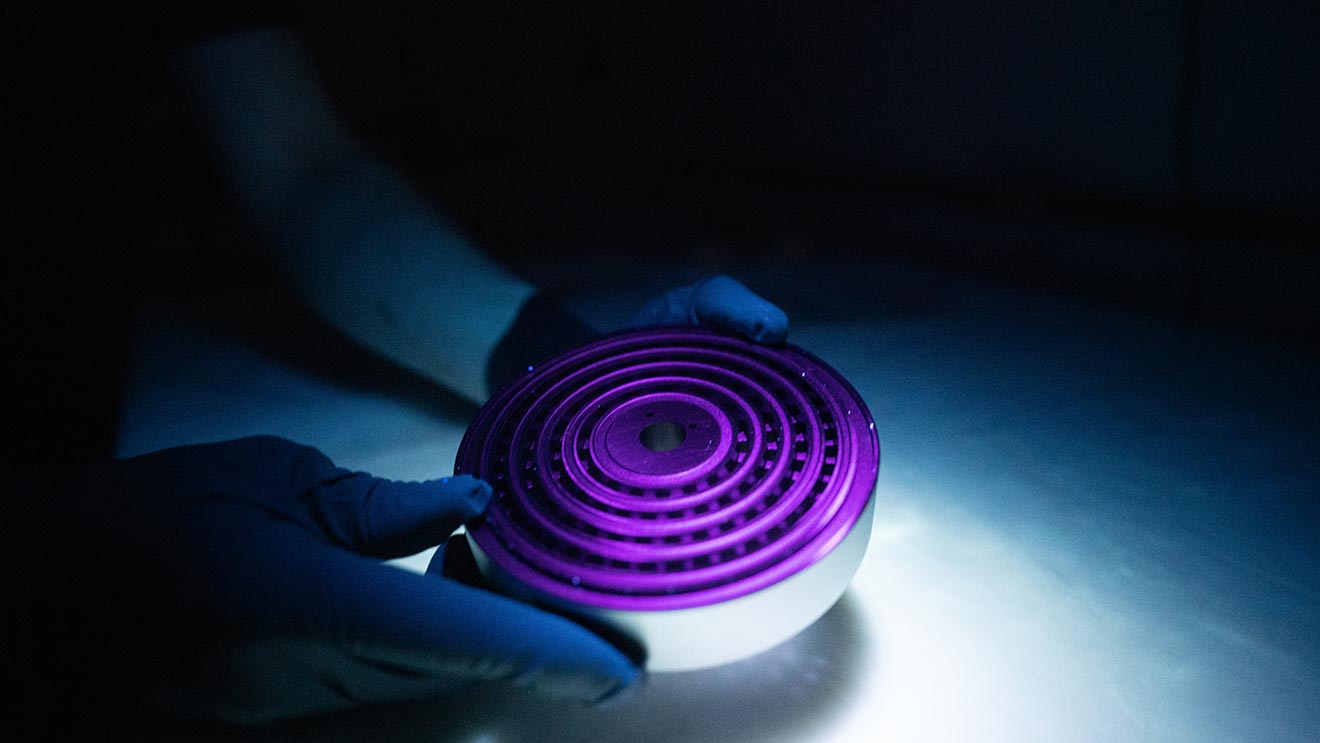

- O2 cleaning

- NDT cell with Level 3 personnel

- Compressor kit boxing capabilities

HOERBIGER services all brands of rotary screw compressors, restoring the equipment to the original equipment manufacturer’s specifications or better. Services include:

- Air end rebuilding

- Drive gear replacement

- Bearings, shaft seals, gaskets, and pre-load spring replacement

- Housing bearing bores and air gap repair

- Rotor bearing journals restored to standard

- Discharge end and inlet housings reground and repaired

- All units are air and vacuum tested

- Rotors and shafts are dynamically balanced

- Lube analysis

- Full service in-house machine shop

- Average rebuild time 5-7 days

- All units carry a one-year warranty

- Preventive Maintenance

- Predictive Maintenance

- Teardowns, rebuilds

- Revamps

- Complete overhauls

- Outages

- Supervision

- Cylinder work

- Regrouting

- Valve retrofits

- Portable compressor analysis

- Engineering staff support

- Windrock analysis

- REE – Reliability, Efficient, Environmentally sound assessments

- Troubleshooting

- Design/drafting

HOERBIGER specializes in repairing and packaging reciprocating compressors used in the refining, petrochemical, gas, and manufacturing industries – including cleaning for oxygen service.

HOERBIGER provides the highest quality parts to the process and industrial compressor market, using an extensive network of suppliers to find parts for virtually any compressor make and model.

Twin arc metal coatings can be applied to components like cylinder liners to restore dimensions, or to provide additional temperature or chemical resistance.

Rolled threads increase the material's fatigue strength and the static loading at the root radius. HOERBIGER can roll threads with diameters ranging from 5/8 inch to 6 inches.

HOERBIGER services all brands of rotary screw compressors, restoring the equipment to the original equipment manufacturer’s specifications or better at our Liberal, Kansas location.

HydroCOM, our stepless capacity control system, reduces energy and operating costs, controls compressor capacity with fast and stepless precision, stabilizes line conditions under dynamic control, and integrates easily into your plant control systems, allowing you to upgrade your existing compressors.

Our certified oxygen cleaning service sanitizes your valves and removes contaminants that can cause safety hazards, impact your product’s purity and reduce your compressor and fleet performance. Our certified clean rooms and high-tech sanitization and examination tools exceed industry standards, ensuring we meet your specific requirements.

From technical and engineering support to shop or field services, we have a solution for all your recip needs

We excel in solving easier and more complex problems for both your shorter and longer-term service needs.

Our highly skilled technicians and best-in-class engineering experts ensure that we get it right the first time, every time.

We continually strive to exceed our customer’s expectations.

Learn more about our products and services here:

HOERBIGER Service Inc.

2500 Nanpap Road

Casper, Wyoming 82601

United States

Phone: +1 307 265 3244

HOERBIGER (Canada) Ltd.

6620 50 Street NW

Edmonton, Alberta T6B 2N7

Canada

Phone: +1 780 440 1872

HOERBIGER Service Inc.

126 McDonald Avenue

Joliet, Illinois 60431

United States

Phone: +1 815 293 3046

HOERBIGER Service Inc.

12206 Fairmont Parkway

La Porte, Texas 77571

United States

Phone: +1 281 474 4458

HOERBIGER Service Inc.

1610 W Pancake Blvd

Liberal, Kansas 67901

United States

Phone: +1 620 626 5073

HOERBIGER (Canada) Ltd.

4181 Sladeview Crescent, Unit 46

Mississauga, Ontario L5L 5R2

Canada

Phone: +1 905 607 0028

HOERBIGER Service Inc.

12700 West Highway 80 East

Odessa, Texas 79765

United States

Phone: +1 432 561 5300

HOERBIGER Service Inc.

3311 LA 1 North

70767 Port Allen, Louisiana

United States

Phone: +1 225 751 3909

HOERBIGER Service Inc.

25057 Anza Drive

Santa Clarita, California 91355

United States

Phone: +1 661 257 2888

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.